Oil and water don’t mix, or so they say, yet in many of today’s industries, there is a growing need for oil-water separators to facilitate processes. In this article, we take a look at 3 levels of oil-water separation, with the aim of helping you to gain an insight into this field.

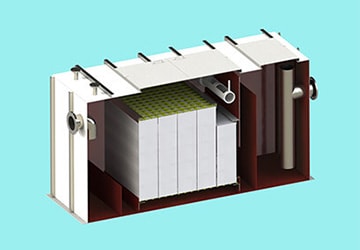

- Above grade oil-water separator – When gravity flows in not on the table, the best solution lies with the oil-water separators from a leading Florida based specialist with all the solutions. The pump feed systems are made from epoxy coated stainless steel and use a high efficiency coalescer (HED) system to remove non-emulsified hydrocarbons. The system flushes solids and removes all oil droplets down to 20 microns, plus there is a wide range of sizes, with single and multiple units, which means the supplier can tailor the system for optimum separation.

- Flush with grade oil-water separator – This is a system that requires a level of gravity flow in order to be effective, plus the system needs its own designated area. Made from structured fiberglass, the system is designed to meet and exceed strict discharge limits set by governments and the HEC components are extremely effective. Benefits include cost-effectiveness, corrosion resistant, lightweight and the system comes with a full 30-year warranty, which is more than impressive. If you feel that failures make us stronger, this blog will appeal to you.

- Below grade oil-water separator – This system is designed for deep burial and drive-over scenarios, and is normally gravity fed. The efficient HEC pack removes oil droplets down to 20 microns, while the system is designed with minimal maintenance in mind, which is an added benefit. The system removes floating oils and settleable solids and hydrocarbons and can be designed for the site. If you would like to learn more about the latest generation of oil-water separators, Google is your best friend and can hook you up with an industry leader who has all the solutions.

Tailored Solutions

Regardless of your facility, there are industry specialists who can carry out an on-site needs assessment and come up with the perfect customized system to handle your oil-water separation processes. If your current system is costly or does not meet with the strict controls, talk to the separation experts and they can design the perfect system that saves you money in the long term.

Performance-Based Industry

The oil-water separation sector is all about performance; the data figures don’t lie and when you need a system that delivers, talk to a leader in the field. One way to discover the provider’s reputation is to check out their client list, which is a true reflection of their standing in the industry. Every business likes to self-promote, it’s the nature of the beast, which is why we need to look at other aspects of the organization.

The US government takes pollution very seriously and there are strict laws in place to govern commercial discharge, which means your processes must comply. Talk to industry experts to find the best oil-water separation system and let them take the strain.